Copper, brass and bronze

Copper has been used by humans for thousands of years because it occurs in nature in a directly usable form. Today, we mainly use copper in electrical components because of its outstanding conductivity.

In its pure form, copper – second only to silver – is the best-known conductor of electricity and heat. As a result, the need for copper is increasing with the green transition, which is driven by electricity.

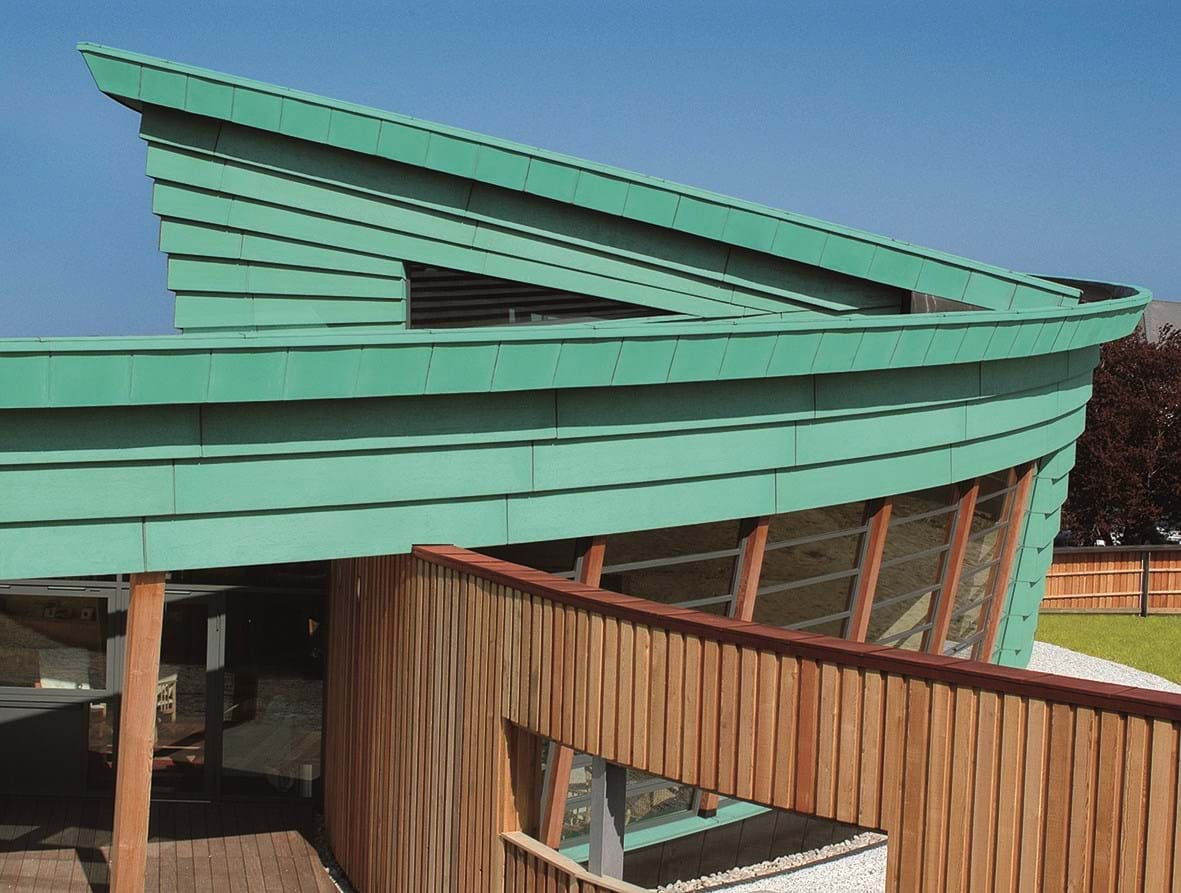

Copper reacts with oxygen and forms a natural protective layer: patina. Over time, the patina layer can develop the unique green colour that we know from statues and copper roofs. The layer protects the metal from corrosion.

What is copper used for?

Copper is often used for electrical components in all industries. Examples include smartphones, electric cars and wind turbines.

Because of its ability to conduct electricity, copper is an important material in the green transition where more and more things will run on electricity.

Copper is naturally antibacterial, which is why it is also widely used in the healthcare and pharmaceutical industries.

Copper is also widely used as facade cladding. You can see examples from our customers here.

Can copper corrode?

Copper cannot rust. But copper can corrode if the chosen alloy is not suitable for the environment.

Copper forms a natural oxide layer that protects against corrosion. Over time this protective layer turns brown or green and is called patina.

Is copper weldable?

Copper is weldable, but not all alloys are well-suited.

The alloy must contain phosphorus and be oxygen-free. CW004A is not suitable, while CW008A and CWo21A are suitable for welding.

The high thermal conductivity means that it takes a little practice to weld copper succesfully.

|

|

Unit |

Copper CW004A (99.9% copper) |

Brass CW614N/ CW617N |

Bronze CC493K |

|

Density |

g/cm3 |

8.9 |

8.47 |

8.83 |

|

Melting point |

°C |

1084 |

875-890 |

860-1020 |

|

Electrical conductivity |

%IACS |

100 |

28 |

12 |

|

Thermal conductivity |

W/m*K |

390 |

123 |

64 |

|

Coefficient of thermal expansion |

μm/m*K |

17 |

19.3 |

18 |

|

Young’s modulus |

Mpa |

110,000 |

97,000 |

101,000 |

|

Chip index |

|

20 |

100 |

85 |

See more in the data sheets for the individual alloys here.

Copper is a quite heavy material, but its good conductivity and extremely high formability offer great advantages. For example, copper can be made into very long, extremely thin strands of wire. The thinner the strands a wire is composed of, the more flexible the wire is.

A copper surface kills bacteria and is naturally antibacterial. This is why copper door handles are sometimes used in healthcare facilities.

How to calculate thermal expansion

Metals expand and contract depending on the temperature.

To account for this, you need to calculate the thermal expansion when copper is to be used in an environment with large temperature fluctuations. An example could be outdoors in Northern Europe where the temperature can easily vary from -20 °C to +30 °C.

The thermal expansion is calculated using the coefficient of thermal expansion (see table under Physical properties).

Example

- A copper sheet (CW004A - coefficient of thermal expansion: 17.0 μm/m*K) is mounted on a façade.

- At -20 °C, the plate is 1000 mm

- At +30 °C, i.e. 50 degrees warmer, the thermal expansion is:

17 μm/(m*K)*1 m*50 K=800 μm=0.85 mm

The plate is 1000.85 mm at +30 °C.

Consult the data sheets for more data on specific alloys.

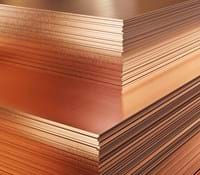

What is the rolling direction?

When a sheet is rolled, the rolling process leaves lines in the material.

The lines are visible on the finished plate, so in some cases it is necessary to account for the rolling direction.

To create a uniform look, plates should be mounted so that the structural lines go in the same direction.

If the plate is to be bent, the rolling direction can affect the bending ability.

To avoid any problems, we ask you to specify the rolling direction when buying sawn sheets/plates. This ensures that the finished sheet has the right properties in relation to the length and width. In this example, the rolling direction of the sheet is 300 mm:

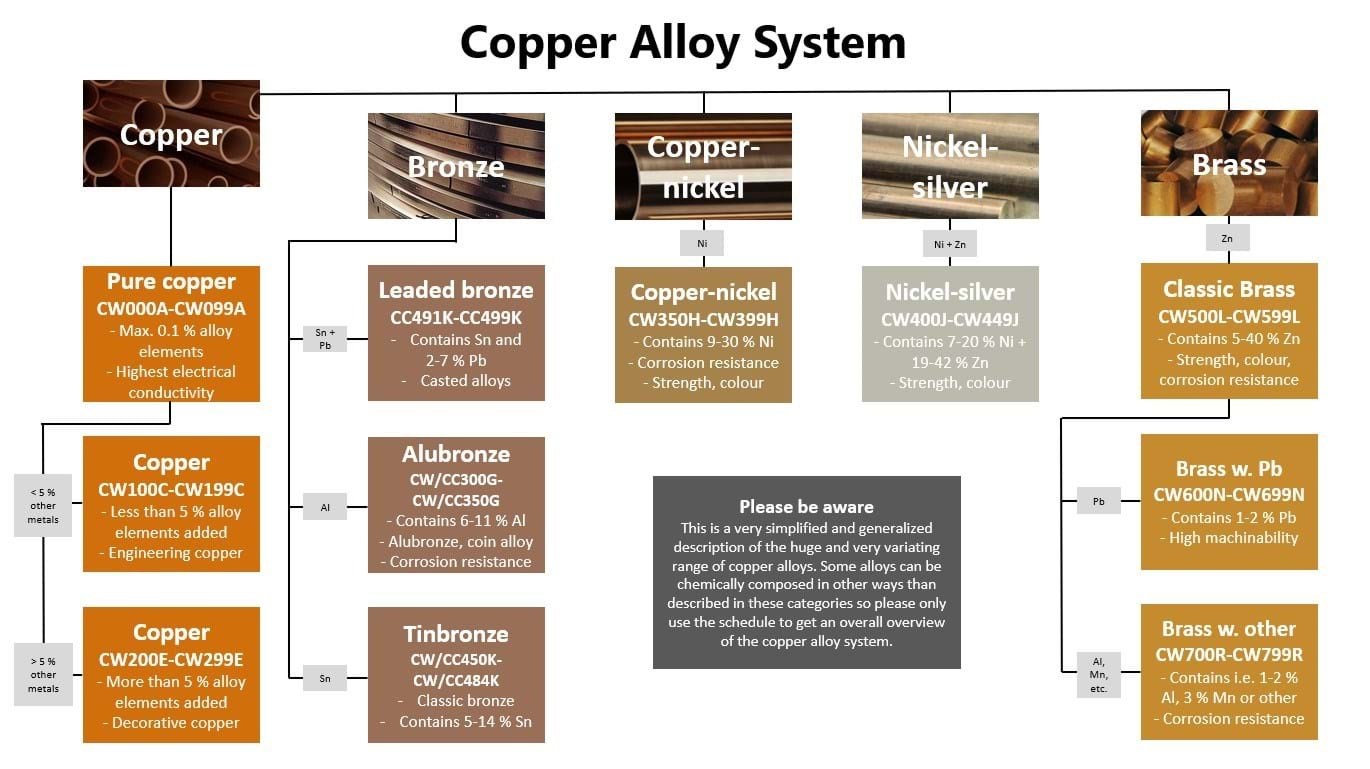

Naming system for copper alloys

Copper alloys are named following a system*. The name consists of:

- A C for copper

- A letter indication the production method

- A 3-digit number

- A letter

For example: CW004A.

The second letter can be B, C or W depending on the production method :

|

Letter |

Production method |

|

B |

Ingot |

|

C |

Cast products |

|

W |

Wrought products |

The number and last letter tells you about the alloying elements:

|

Series |

Letter |

Metal type/name |

Comments |

Example |

|

000 - 099 |

A or B |

Pure copper |

High electrical conductivity |

CW000A |

|

100 - 199 |

C or D |

Copper |

Less than 5 % alloying elements |

CW100C |

|

200 - 299 |

E or F |

Copper |

More than 5 % alloying elements |

CW200E |

|

300 - 349 |

H |

Alubronze |

Coin alloy |

CW300G |

|

350 - 399 |

H |

Cupronickel /copper-nickel |

Marine applications |

CW350H |

|

400 - 449 |

J |

Nickel-silver |

Decorative appearance |

CW400J |

|

450 - 499 |

K |

Bronze |

Classic bronze |

CW450K |

|

500 - 599 |

L or M |

Brass |

Classic brass |

CW500L |

|

600 - 699 |

N or P |

Brass with lead |

Good machinability |

CW600L |

|

700 - 799 |

R or S |

Brass with Al, Mn or other |

Good corrosion resistance |

CW700R |

*EN 1412 - Copper and copper alloys - European numbering system

Brass is an alloy of copper and 5-40% zinc. The higher the zinc content, the more yellow the metal becomes – the characteristic brass colour.

Brass is more corrosion-resistant than pure copper, and it has better mechanical properties such as strength and malleability. Brass is also very suitable for machining. On the other hand, the zinc content means that brass has a lower conductivity than pure copper.

Bronze is usually an alloy of copper and tin, but there are also bronze alloys with other metals, for example copper and aluminium or copper and lead.

Copper is alloyed with lead or tellurium for better machineability. Lead and tellurium make the chips shorter and harder, so they do not get in the way of machining.

However, the use of lead is limited by the EU’s RoHS and REACH legislation to reduce health risks.

In recent years, some manufacturers have developed alloys with a low lead content that are still suitable for machining. An example is the brass alloy CW724R (Eco Brass).

Generally speaking, brass is one of the most machinable metals. The chip index for metals is based on the brass alloy CW614N (index 100), i.e. the most suitable alloy for machining. Pure copper alloyed with tellurium, CW118C, is approximately index 80 and pure copper, CW004A, is approximately index 20.

Conductivity

Electrical conductivity

Pure copper has a very good electrical conductivity, which is why about 2/3 of all mined copper today is used in electrical applications such as wires or electrical components.

The conductivity of copper is so good that the standard for measuring the conductivity of metals is determined by copper. Conductivity is measured in %IACS (International Annealed Copper Standard), where copper is 100%.

Thermal conductivity

Copper also has very good thermal conductivity. In electrical applications, copper will quickly disperse the heat.

This makes copper even more suitable for these applications because excess heat in an electrical component causes unnecessary resistance to the electric current. In this case, good thermal conductivity improves the electrical conductivity.

Most short circuits of electrical appliances are caused by overheating. Maybe you have experienced it yourself on a hot summer day: Most modern smartphones are designed to turn off if they become overheated, for example from lying in the sun.

Patina on copper

Copper reacts with atmospheric air and forms a thin layer of copper oxide on the copper surface. This is known as patina.

The copper oxide protects the copper from further degradation/corrosion, and over time the colour develops into the unique green colour we know from old copper roofs or statues such as the Statue of Liberty in New York.

Patina on facades

The oxidization process can be sped up in production so that the materials are delivered with patina. This is especially used for facade projects to create a warm and "authentic" look.

A vertical surface, where water and pollution can easily run off, will patinate significantly slower than a horizontal surface. The deep brown patinated look will take several year to develop on a vertical surface if the sheets are not pre-patinated. Green patina takes even longer.

On a horizontal surface, rain water and other contaminants stay on for longer and has more time to react with the copper. Here you can expect to see deep brown patina after about 8-15 years.

A surface in an urban area or near the sea will patinate faster than a surface in a rural setting.

The patina is a natural process, and the colour will change over time and depending on the environment.

Recycling of copper

Copper is widely recycled and remelted into new products.

Compared to other industrial metals, copper is expensive, and there is virtually no waste – all scrap is recycled.

Some copper mills offer closed-loop recycling. This means that customers can return their copper scrap to the mill for recycling and receive "the same" copper again as a finished product.