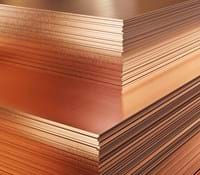

Hokotol 140 x 1520 x 3020 mm

Hokotol

Has a high strength alloy with a high strength though all the plate thickness. The alloy has a low corrosion resistance and a strength as high as several steel variants. Is usable for aircraft's, military purposes and plastic-moulded forms (welded 7075). The advantage by HOKOTOL is that the material does not change properties under the machining.

We are not liable for items out of stock. The specified weight is theoretical. Please contact us if you have any further enquiries.

Alloys

| Density | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | g/cm3 | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Rest |

| Hokotol | 2.83 | 0.3 | 0.35 | 1.5 | 2.6 | 0.1 | 1.8 | 2.6 | 0.05 | 5.7 | 7.6 | 0.06 | 0.08 | 0.25 | 0.15 | Al, Aluminium |

Aluminium Properties

| Thermal conductivity | Coefficient of thermal expansion | Electrical conductivity | |

|---|---|---|---|

| Alloy | W/m*K | µm/(m*K) | %IACS |

| Hokotol | 154 | 23.5 | 39.7 |

Mechanical properties

| Tensile strength (Rm) MPa | Proof stress (Rp0,2) | Thickness interval | Elongation A50mm | |||

|---|---|---|---|---|---|---|

| Norm | Alloy | Temper | Rm N/mm2 | MPa | mm | % min |

| EN 485-2:2008 | Hokotol | T651 | 550 | 495 | 100 | 4 |

| EN 485-2:2008 | Hokotol | T651 | 500 | 430 | 200 | 1 |

| EN 485-2:2008 | Hokotol | T651 | 460 | 400 | 300 | 1 |

| EN 485-2:2008 | Hokotol | T651 | 450 | 390 | 325 | 1 |